Insulated Panel Services

Mid Thumb Contracting Group Insulated Panel Services has two main product lines: Low Temperature Construction and Roofing. We have the technical know-how and experience to provide insulated panels for low-temperature, commercial and industrial facilities.

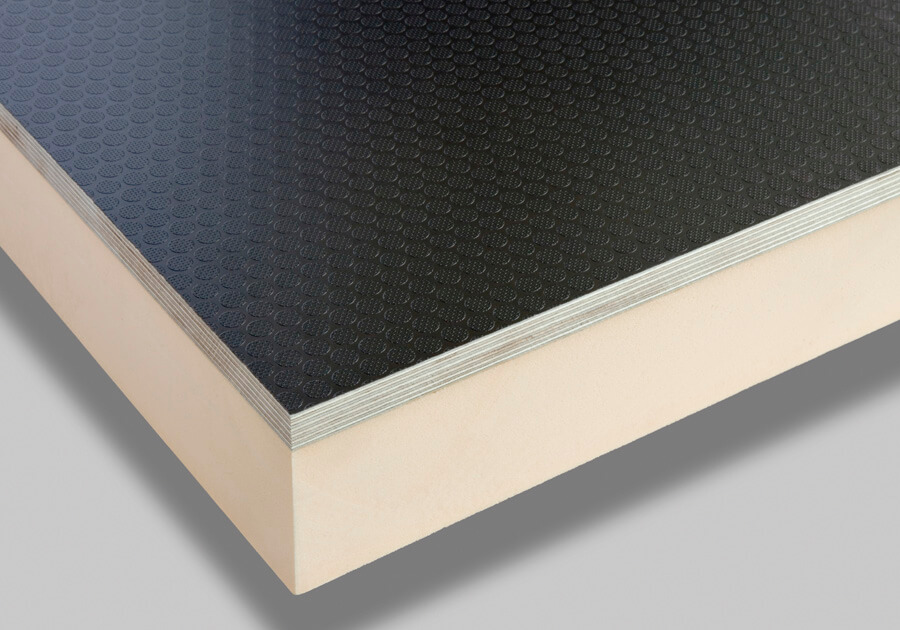

Insulated Metal Panels

Installing insulated panels is our core work. We use these energy-efficient, clean, and bright panels to form the ceilings and walls of freezers, coolers, and other temperature-controlled environments where it is critical to the integrity of product and/or manufacturing process. Additionally, Mid Thumb uses panels in the construction of manufacturing and commercial facilities. We utilize this material in new construction, renovations, and expansions. Our approach adds value to our customer; value derived from ROI savings in performance, appearance, and reduced facility maintenance costs.

Mid Thumb specializes in three main categories of insulated panels in a variety of insulation thicknesses:

- Urethane Foam Core

- Expanded Polystyrene Skin (EPS) Core

- Fire Rated Panels (Mineral Wool Core)

Each panel composite has unique insulating, fire protection, and spanning capabilities. Mid Thumb understands each application and will help you choose the right insulated panel to match your need.

Mid Thumb is well-versed in the variety of panel finishes offered and can help you choose the correct materials for your project. Whether your needs are for Good Manufacturing Processes (GMP), USDA compliance, or you utilize caustic wash-down in your processes, we understand the finishes and their unique characteristics. Below are a few options we provide on our installations, depending upon the specific requirements for your job:

- USDA Approved Finishes

- Stainless Steel

- Fiberglass Reinforced Plastic (FRP)

- Architectural Finishes

Doors

Door selection is critical to designing the end use of your facility. Considerations to material movement, number of cycles, insulation requirements, personnel movement, and egress are only some of the concerns that need to be part of the design criteria. Mid Thumb installs a variety of doors and each has their unique applications to consider. Below is a snapshot of the variety of door types we install daily:

- Insulated Cooler Doors

- Insulated Freezer Doors

- High Speed Doors

- Traffic Doors

- Fiberglass Reinforced Plastic (FRP) Doors

- Hollow Metal Doors

- Strip Curtains

Not only does Mid Thumb install these doors for new construction or renovations, we also provide essential maintenance services to these doors. Doors are paramount to your facility operation. If not maintained, they can cause thermal loss, loss of production from your employees, or even pose a safety risk if the safety devices are no longer operational. Mid Thumb can maintain, troubleshoot, and replace worn door components or the doors entirely. Our team understands how important these doors are in your operations and has the expertise to help you maximize your investment.

Vapor Barriers

The most critical component to any low-temperature installation is the integrity of a monolithic vapor barrier. Mid Thumb understands how fundamental this is for the continuing operation of your facility. A failing vapor barrier system can cause moisture infiltration, frosting, and ice build-up; all characteristics that are negative to a low-temperature environment.

We install vapor barriers under slabs in freezer and certain cooler configurations. Our team will ensure that this vapor barrier connects correctly to the exterior wall system. Mid Thumb is also very knowledgeable in another critical vapor barrier situation: the roof-to-wall juncture. This detail is especially problematic if your selected roofing contractor does not understand the importance of a solid vapor barrier system.

Combined with our roofing services, Mid Thumb has the capability to successfully install a quality system for this vital area on your low temperature facility. If you have an existing facility and you suspect vapor intrusion, please contact to investigate and offer a comprehensive solution.

Floor Insulation

Mid Thumb insulates floors and allied floor parts to improve thermal performance in buildings. In cold storage facilities, floors are insulated to create the proper thermal moisture barrier. Insulation material R-values, density, and compressive strength vary. These are items to consider especially when your facility is a heavy duty freezer or other refrigerated area where thermal and moisture vapor control is critical.

The Mid Thumb team understands the importance of the details, like ensuring the proper staggering of multi-layered installations and confirming all gaps between insulation boards are tight. Floor insulation is crucial to the longevity of your low-temperature finished floor.

Roofing Services

The roofing services provided by Mid Thumb are vast in different material and installation methods. From repairs or maintenance to existing roofing or new installations, Mid Thumb is your first choice for a comprehensive roofing contractor. Mid Thumb boasts a whopping combined installation experience at management levels of more than 100 years of roofing. While we specialize in low-temperature roofing, we also have the expertise to provide services to the commercial and industrial markets.

Architectural Insulated Metal Panels

The cost of energy is expensive. Any operational efficiency you can design into your building gives you an edge over your competition. Architectural insulated metal panels offer a highly energy-efficient and very aesthetically pleasing solution. With a wide variety of finishes, textures, and color schemes available, why would you not consider upgrading your facility?

Serving all of South East Michigan and beyond. Please contact our office at 586-646-5490